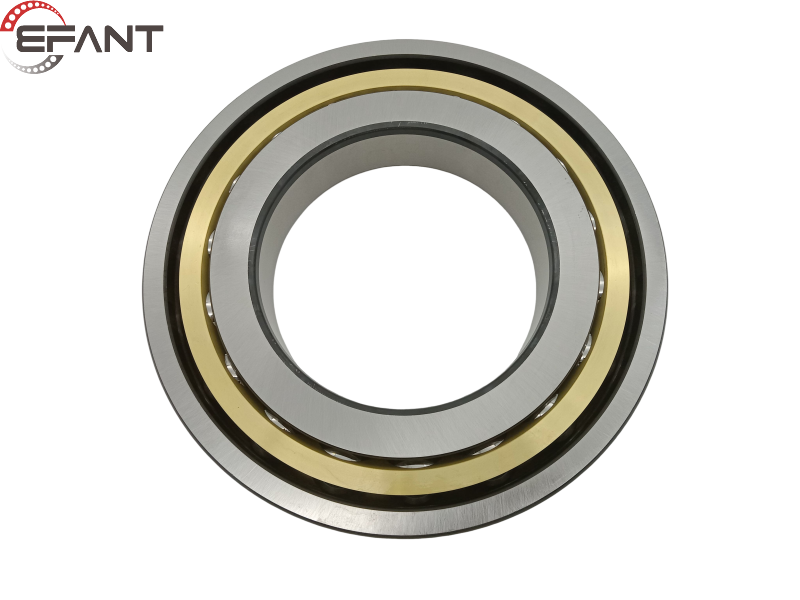

Angular contact ball bearings are designed to withstand high axial and radial loads while operating at high speeds. However, several factors can contribute to their failure:

1.Overloading: Excessive axial or radial loads beyond the bearing's rated capacity can lead to fatigue failure, causing cracks to develop in the raceways and rolling elements.

2.Misalignment: Improper alignment of shafts can result in uneven loading on the bearing, causing premature wear and failure. Angular contact bearings are particularly sensitive to misalignment.

3.Improper installation: Incorrect installation practices such as inadequate lubrication, improper mounting, or using the wrong fitting techniques can lead to premature failure of the bearings.

4.Insufficient lubrication: Lack of proper lubrication or using the wrong type of lubricant can increase friction and heat generation, leading to premature wear and ultimately failure of the bearings.

5.Contamination: Dust, dirt, moisture, and other contaminants can enter the bearing housing, leading to abrasive wear, corrosion, and ultimately bearing failure.

6.Fatigue: Continuous cycling of loads, especially under heavy loads or high speeds, can lead to fatigue failure over time, resulting in cracks and eventual bearing failure.

7.Material defects: In rare cases, manufacturing defects or poor-quality materials can compromise the integrity of the bearing, leading to premature failure.

8.Operating conditions: Extreme temperatures, shock loads, and vibration can all contribute to bearing failure if the bearings are not properly designed or selected for these conditions.

9.Improper maintenance: Neglecting regular maintenance such as monitoring bearing condition, lubrication schedules, and replacement of worn components can lead to unexpected failures.

To prevent angular contact ball bearing failures, it's essential to adhere to proper installation procedures, ensure correct alignment, provide adequate lubrication, prevent contamination, and monitor operating conditions regularly. Additionally, selecting bearings with appropriate load capacities and operating parameters for the application is crucial for maximizing bearing life and performance.

If you have any needs, you can contact us at any time.

Mar-18-2024

Trade Shows&Event

What is the effect of pickling treatment on bearings? More InformationMar-12-2024

Trade Shows&Event

What are the applications of high-speed precision angular contact ball bearings in electric spindles? More InformationMar-11-2024

Trade Shows&Event

What are the advantages of Gcr15 steel? More InformationSubmit Request