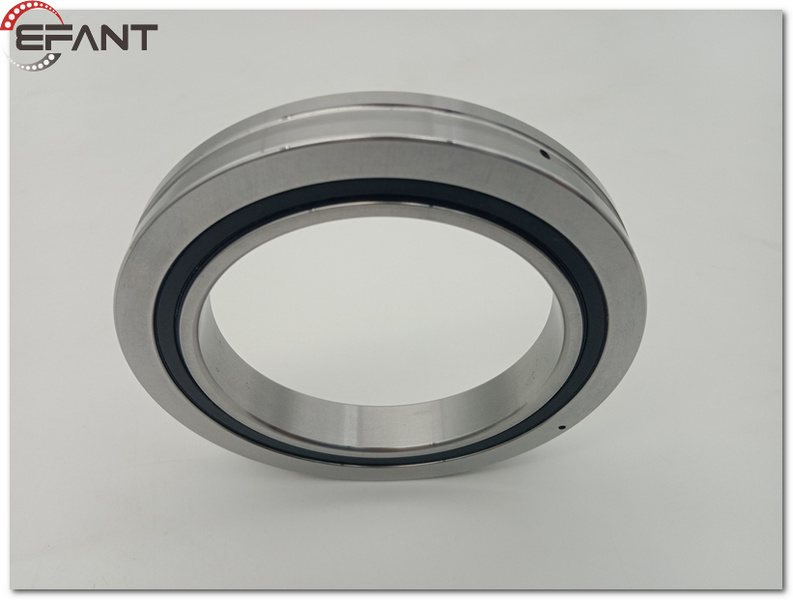

Cross roller bearings are commonly used in the robot industry for several reasons:

1.High Load Capacity: Cross roller bearings are designed to handle high axial and radial loads simultaneously. This is crucial in robotics, where robots often need to carry heavy payloads while maintaining precise positioning and movement.

2.Compact Design: Cross roller bearings have a compact and space-saving design. This is advantageous in robotics where space is often limited, and compact components are essential for creating more efficient and agile robots.

3.High Precision: These bearings provide high levels of precision and accuracy in positioning and motion control. In robotics, especially in applications like pick-and-place operations or assembly tasks, precision is critical for achieving reliable results.

4.Low Friction: Cross roller bearings are known for their low friction characteristics, which contribute to efficient and smooth movement. Reduced friction helps in conserving energy and extending the life of the robot's components.

5.Rigidity: They offer high rigidity, ensuring minimal deformation or flexing when subjected to external forces. This rigidity helps maintain stable and predictable robot movement, particularly in applications where the robot needs to maintain its position against external loads.

6.Durability: Cross roller bearings are designed for durability and long service life. They can withstand repeated use, which is important in industrial robot applications where robots often operate continuously.

7.Variety of Sizes and Configurations: Cross roller bearings come in various sizes and configurations, allowing engineers to choose the most suitable type for their specific robot design and load requirements.

8.Low Maintenance: These bearings typically require minimal maintenance, reducing downtime and maintenance costs for robotic systems.

9.Environmental Resistance: Cross roller bearings can be designed to withstand harsh environmental conditions, including dust, humidity, and temperature extremes. This makes them suitable for a wide range of robotic applications, including those in challenging environments like manufacturing plants or outdoor settings.

10.Customization: Manufacturers can customize cross roller bearings to meet the specific needs of a robot design. This includes adjusting size, load capacity, and other parameters to optimize performance.

11.Industry Standardization: Cross roller bearings are often manufactured according to industry standards and specifications, ensuring compatibility with various robotic systems and components.

In summary, cross roller bearings are favored in the robot industry due to their ability to provide high load capacity, precision, and durability in a compact and efficient design. These characteristics make them a suitable choice for a wide range of robotic applications, from industrial manufacturing to precision medical and surgical robots.

Sep-26-2023

Trade Shows&Event

What is the effect of acid cleaning treatment on bearings? More InformationSep-25-2023

Trade Shows&Event

What are the factors that cause the fracture of angular contact ball bearings? More InformationSep-20-2023

Trade Shows&Event

What harm can low-quality lubricating oil cause to bearings? More InformationSubmit Request