The steel balls in deep groove ball bearings are typically placed between the outer ring and the inner ring within a raceway or groove that is designed to hold and guide the balls. Here's a basic overview of how this is done:

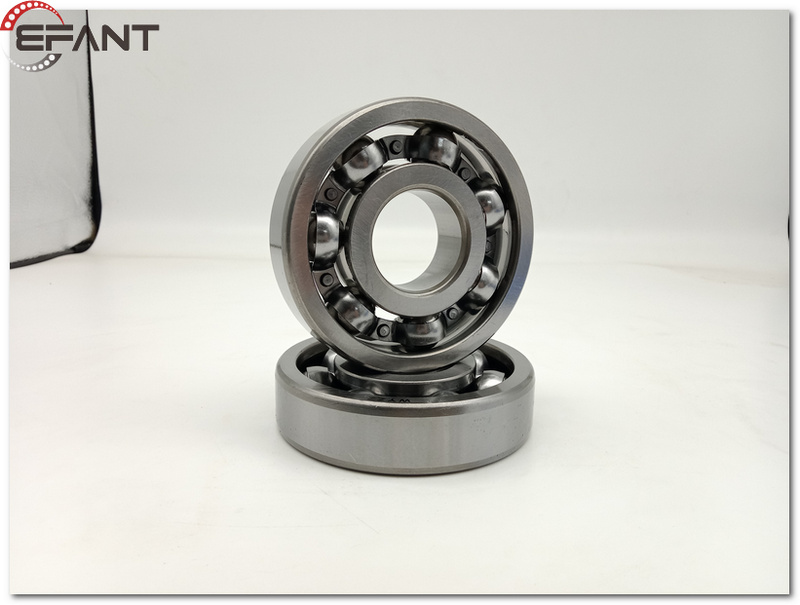

1.Outer Ring and Inner Ring: Deep groove ball bearings consist of an outer ring (also known as the outer race) and an inner ring (also known as the inner race). These rings have grooves or raceways on their inner and outer surfaces.

2.Ball Placement: The steel balls, which are typically spherical in shape, are placed between the inner and outer rings. The number of balls can vary depending on the design and size of the bearing. The balls are evenly spaced within the raceway.

3.Ball Retainers: In some bearings, especially larger ones, ball retainers or cages may be used to maintain proper spacing and alignment of the balls. These retainers are often made of materials like plastic or metal and help prevent the balls from rubbing against each other, reducing friction and wear.

4.Assembly: The assembly process is typically automated in manufacturing facilities. Specialized machinery is used to place the balls into the raceway while ensuring they are evenly distributed.

5.Sealing and Lubrication: After the balls are placed, the bearing may be sealed to protect it from contaminants and to retain lubrication. Seals or shields are used to enclose the bearing, and lubricating grease is added to ensure smooth rotation.

6.Closure: Once the balls, seals, and lubrication are in place, the bearing is typically closed or sealed to complete the assembly. The sealing methods can vary, and the specific type of bearing (e.g., open, shielded, or sealed) will determine how it is closed.

Please do not hesitate to contact us with any requirements.

Nov-07-2023

Trade Shows&Event

What are the treatment methods of oil leakage from the bearing end cover of harmonic reducer? More InformationNov-01-2023

Trade Shows&Event

What parts does a bearing consist of? More InformationOct-31-2023

Trade Shows&Event

What issues should be paid attention to when using spherical roller bearings? More InformationSubmit Request