Thrust ball bearings and deep groove ball bearings are two different types of ball bearings designed for specific applications and load-bearing requirements. Here are the key differences between them:

1.Load Direction:

★Thrust Ball Bearings: These bearings are designed to primarily handle axial (thrust) loads, which are forces applied parallel to the axis of the bearing. They are optimized for applications where the main concern is managing axial forces, such as in automotive transmissions or thrust loads in machinery.

★Deep Groove Ball Bearings: These bearings are primarily designed to handle radial loads, which are forces applied perpendicular to the axis of the bearing. They are commonly used for applications where the primary load is radial, such as in electric motors or conveyor systems.

2.Design and Configuration:

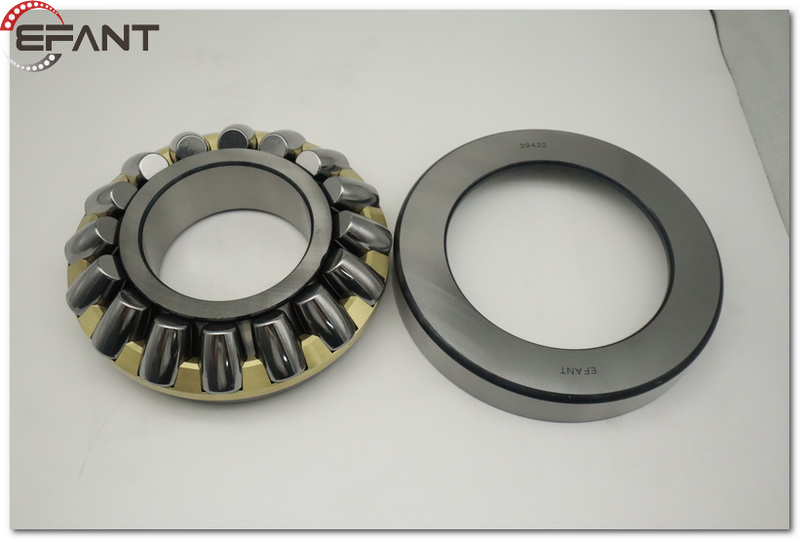

◊Thrust Ball Bearings: Typically consist of two grooved washers (raceways) with ball bearings sandwiched between them. They allow for rotational movement along the axis of the bearing while handling axial loads.

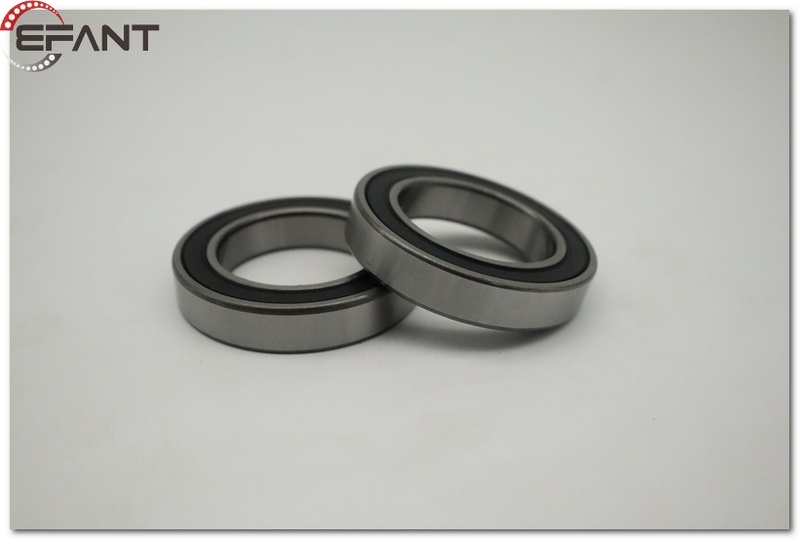

◊Deep Groove Ball Bearings: Have a single, deep, uninterrupted groove on the inner and outer races, enabling them to accommodate radial loads and moderate axial loads. They are more suited for high-speed applications.

3.Axial Load Capacity:

✪Thrust Ball Bearings: Excel at handling axial loads and are designed to withstand substantial thrust forces. They can support both single-direction and double-direction thrust loads.

✪Deep Groove Ball Bearings: Are not optimized for handling axial loads but can tolerate some axial load. They are primarily chosen for their ability to handle radial loads efficiently.

4.Lubrication and Speed:

☼Thrust Ball Bearings: Generally used in applications with lower speeds compared to deep groove ball bearings. Adequate lubrication is crucial to reduce friction and heat generation.

☼Deep Groove Ball Bearings: Suited for high-speed applications due to their design and the ability to handle radial loads efficiently. They often require less lubrication compared to thrust ball bearings.

5.Application Examples:

❤Thrust Ball Bearings: Commonly found in automotive transmissions, machine tool spindles, and applications where axial loads need to be managed.

❤Deep Groove Ball Bearings: Widely used in electric motors, fans, pumps, skateboards, and various industrial machinery where radial loads predominate.

You can contact us if you have any requirements!

Sep-20-2023

Trade Shows&Event

What harm can low-quality lubricating oil cause to bearings? More InformationSep-18-2023

Trade Shows&Event

What are the installation for deep groove ball bearings? More InformationSep-13-2023

Trade Shows&Event

What is the reason for the shaking of the rotary table bearing? More InformationSubmit Request