Rolling bearings are mechanical components that support the rotation of moving parts in machinery and equipment. They are designed with specific load capacity, speed, and durability requirements in mind.The materials used to make rolling bearings affect their durability, resistance to wear, and ability to handle high temperatures and loads. Common materials include steel, ceramic, and polymer.

They can handle both radial and axial loads and are used in a wide range of applications, including automotive, aerospace, industrial machinery, and consumer products.

There are several types of rolling bearings, each designed to handle different types of loads and operating conditions. The most common types of rolling bearings are:

1.Ball bearings: These bearings use balls to reduce friction and support radial and axial loads. They are suitable for high-speed applications and are commonly used in machinery and equipment, including electric motors, pumps, and conveyor systems.

2.Roller bearings: These bearings use cylindrical, tapered or spherical rollers to reduce friction and support heavy radial and axial loads. They are used in applications such as mining equipment, heavy machinery, and construction equipment.

3.Needle bearings: These bearings use long and thin rollers to reduce friction and support heavy loads. They are commonly used in automotive and aerospace applications, as well as in industrial machinery.

4.Thrust bearings: These bearings are designed to handle axial loads, such as those generated by gears or motors. They are commonly used in automotive transmissions, machine tools, and marine propulsion systems.

5.Tapered roller bearings: These bearings use tapered rollers to reduce friction and support heavy radial and axial loads. They are commonly used in automotive and industrial applications, such as wheel bearings and gearboxes.

6.Spherical roller bearings: These bearings use spherical rollers to reduce friction and support heavy radial and axial loads. They are commonly used in applications where misalignment is a concern, such as in conveyor systems and printing presses.

7.Cylindrical roller bearings: These bearings use cylindrical rollers to reduce friction and support heavy radial loads. They are commonly used in applications such as machine tool spindles, gearboxes, and rolling mills.

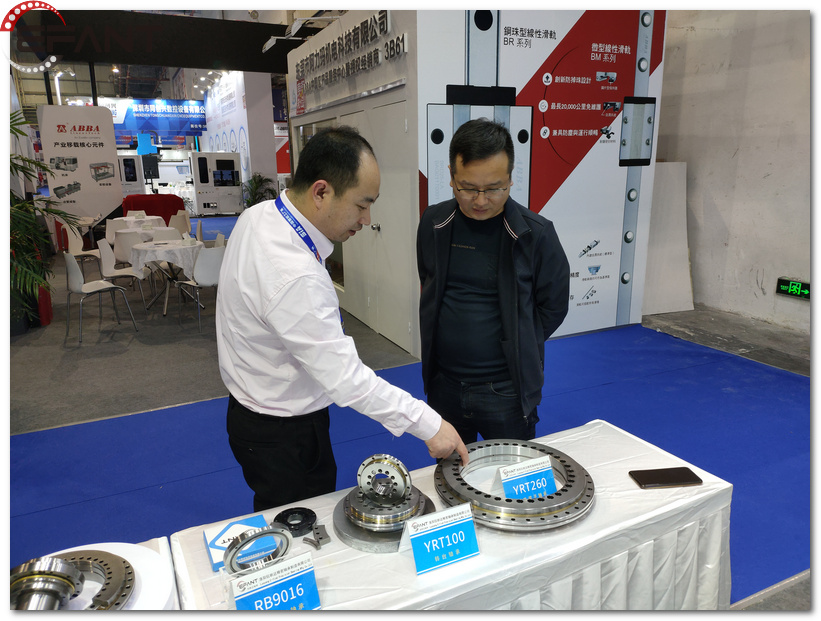

Luoyang E-find Precision Bearing specializes in the production of high-precision, high-rigidity,

heavy-load crossed roller bearings, rotary table bearings, harmonic bearings and customized

bearings for 18 years.We have ISO, SGS certification, and professionally replaces IKO THK INA SKF and other foreign imported brands.

All bearings are processed by advanced CNC machine tools, ground three times by precision grinders, 100% inspected after each processing. All our bearings guaranteed for one year in normal working condition.

Our cross roller bearing and YRT rotary table bearings are widely used in robots, automated production lines, machine tools accessories and other industries.

Our bearings are exported to more than 50 countries, such as the United States, Europe, South Korea, Japan, etc., and enjoy high reputation at home and abroad.

Our company value is let our custom succeed, so choose us is to choose high quality, choose rest assured. And we also welcome you to visit our factory, so please feel free to contact us if you have any requirements and want to know more about us.

Mar-28-2023

Trade Shows&Event

What are bearing rolling elements More InformationMar-27-2023

Trade Shows&Event

Why rotary table bearings can be applied to CNC rotary table? More InformationMar-24-2023

Trade Shows&Event

What type of roller bearings are used for CT machine main bearings? More InformationSubmit Request