Model of turntable bearing:

There are many models of turntable bearings, and the common ones are as follows:

1: Single row four point contact ball turntable bearings

2: Double row unequal distance steel ball turntable bearings

3: Three row needle roller turntable bearings

4: Single row cross roller turntable bearing

5: Double row angular contact ball turntable bearings

6: Each model of turntable bearing has its specific application range and working principle.

Working principle of turntable bearings:

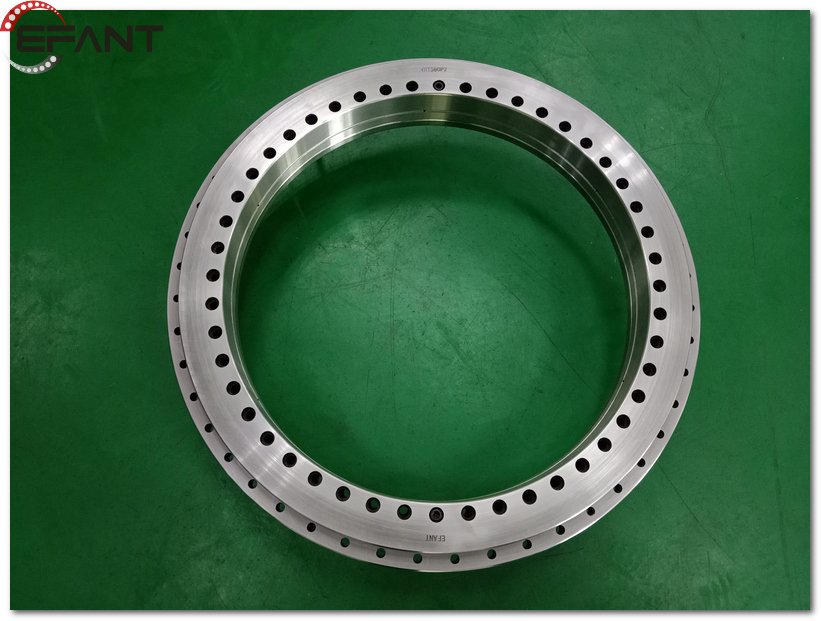

The turntable bearing is composed of inner and outer rings, rolling elements, and retainer, among which the rolling element is a key component. It usually uses steel balls, cylinders, or cones to withstand weight and rotational force through rolling. When the turntable bearing rotates, the rolling element rolls between the inner and outer rings, thereby completing the rotational motion of the entire mechanical equipment.

The turntable bearing also has self-lubricating function, which can form an extremely thin oil film between the inner and outer rings and rolling elements, thereby reducing friction and wear, and extending the bearing life.

Application of turntable bearings;

Rotary table bearings are widely used in various mechanical equipment, such as automobiles, ships, wind turbines, cranes, rotary tables, etc. Among these devices, the turntable bearings play an important role in ensuring smooth rotation and operation of the entire equipment.

The model and working principle of the turntable bearing are very important. Choosing the appropriate model according to different application scenarios and needs can improve the efficiency and reliability of mechanical equipment. In the future, with the continuous development of industrial technology, the models and working principles of turntable bearings will also be constantly updated and improved, providing more reliable guarantees for the operation of various mechanical equipment.

You can contact us if you have any requirements!

May-15-2024

Trade Shows&Event

How to purchase turntable bearings? More InformationMay-14-2024

Trade Shows&Event

What are the installation techniques for YRT turntable bearings? More InformationMay-11-2024

Trade Shows&Event

What type of equipment is the main use of large turntable bearings? More InformationSubmit Request