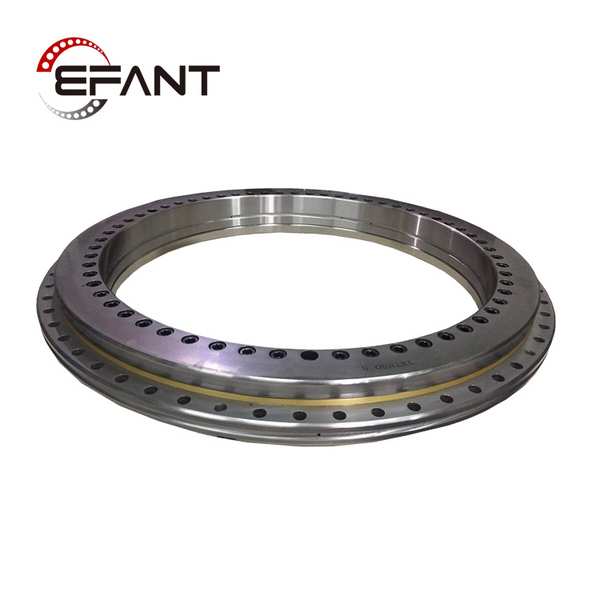

The YRT turntable bearing is a type of bearing similar to the three row roller combination slewing support structure. Compared to the three row roller combination slewing support structure, it has the characteristics of small size, high accuracy level, high rigidity, large load-bearing capacity, and resistance to damage. Mainly used in high-precision CNC turntables, CNC indexing discs, vertical machining centers, vertical grinders, military radars, precision medical equipment, etc.

So how was the YRT turntable bearing installed through analysis?

1. The bearing enters the housing.

2. The outer diameter of the YRT turntable bearing matches the clearance between the bearing seat.

3. Tighten the outer ring mounting screws in a cross pattern in sequence.

4. The table of the CNC turntable is pressed against the end face of the bearing.

5. The YRT turntable bearing, as another part of the end face, can be installed in conjunction with the flange plate

6. Install the interference fit between the outer diameter of Taizhou and the inner diameter of the bearing.

7. Align the turntable bearings and the mounting holes on the turntable.

8. Cross tighten the inner ring connecting screws once.

9. The connecting screws run through the flange, and the bearings are locked on the surface of the turntable.

10. If the bearing is extremely difficult to rotate, loosen the installation bolts and re tighten in three steps in a cross order to eliminate bearing deformation.

Please feel free to contact us if you have any requirements.

May-15-2024

Trade Shows&Event

How to purchase turntable bearings? More InformationMay-11-2024

Trade Shows&Event

What type of equipment is the main use of large turntable bearings? More InformationMay-09-2024

Trade Shows&Event

Do you truly understand rotary table bearings? More InformationSubmit Request