Wind power bearings have several critical applications in wind turbines, both onshore and offshore. Here are the primary areas where wind power bearings are utilized:

1.Main Shaft Bearings: Wind turbines have large main shaft bearings that support the main rotor shaft. These bearings enable the rotation of the rotor and transfer the generated mechanical energy to the generator. Main shaft bearings are subjected to high loads and must withstand both radial and axial forces.

2.Blade Pitch Bearings: In pitch-controlled wind turbines, the blade pitch bearings allow for adjustment of the angle of the turbine blades. These bearings enable the blades to rotate around their longitudinal axes, allowing for optimal aerodynamic performance. Blade pitch bearings must handle both rotational and tilting forces.

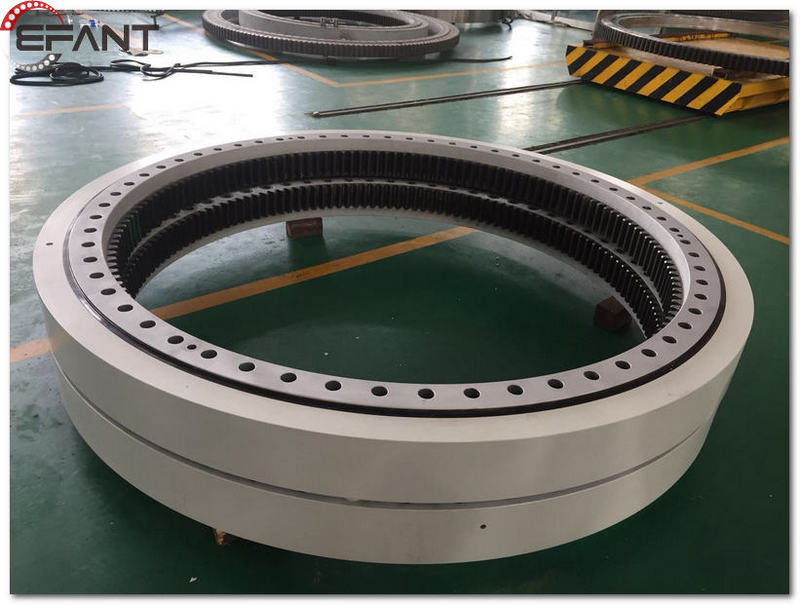

3.Yaw Bearings: Yaw bearings facilitate the rotation of the nacelle and rotor assembly to face the wind direction. These bearings are responsible for orienting the wind turbine and are subject to substantial loads and moments. Yaw bearings must have excellent load-carrying capacity and low friction to enable smooth and efficient yawing operation.

4.Generator Bearings: Wind turbine generators, which convert mechanical energy into electrical energy, rely on specific bearings for their operation. Generator bearings support the rotor and handle the loads generated during rotation. These bearings are typically designed to minimize friction and maintain high rotational speeds with minimal energy loss.

5.Gearbox Bearings: Some wind turbine designs incorporate gearboxes to increase the rotational speed of the generator. Gearbox bearings support the shafts and gears within the gearbox. They must handle both radial and axial loads while ensuring smooth and efficient power transmission.

6.Pitch Bearing Rings: Pitch bearing rings are large-diameter bearings used in the blade pitch system. These bearings are mounted between the blade root and the hub, allowing the blades to rotate. They play a crucial role in controlling the pitch angle and ensuring the safe and efficient operation of the wind turbine.

Wind power bearings are subjected to demanding operating conditions, including high loads, continuous rotation, and exposure to harsh environments. They are designed to withstand these conditions while maintaining reliability and durability over the turbine's operational lifetime. Advanced bearing technologies, materials, and lubrication systems are employed to enhance performance, reduce maintenance requirements, and optimize energy efficiency in wind turbine applications.

May-19-2023

Trade Shows&Event

Why can cross roller bearings be used in drills More InformationMay-17-2023

Trade Shows&Event

Which bearings are suitable for semiconductor manufacturing More InformationMay-12-2023

Trade Shows&Event

Can cylindrical roller bearings be used in X-ray machine More InformationSubmit Request