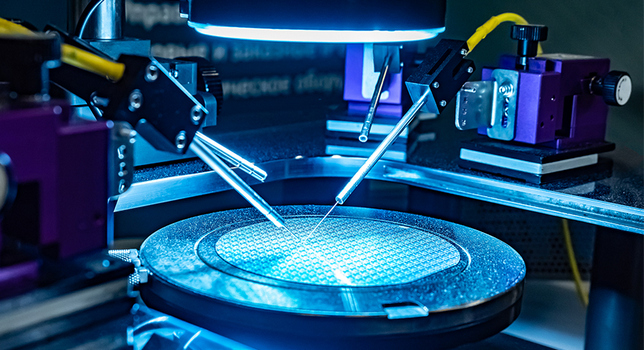

Semiconductor manufacturing, also known as semiconductor fabrication or chip manufacturing, refers to the process of creating integrated circuits (ICs) or chips, which are the building blocks of modern electronics. Semiconductor manufacturing involves a series of complex steps to transform raw materials into finished semiconductor devices capable of performing various electronic functions.

Several types of bearings are suitable for semiconductor manufacturing due to their specific characteristics and performance capabilities. Here are some commonly used bearings in semiconductor manufacturing:

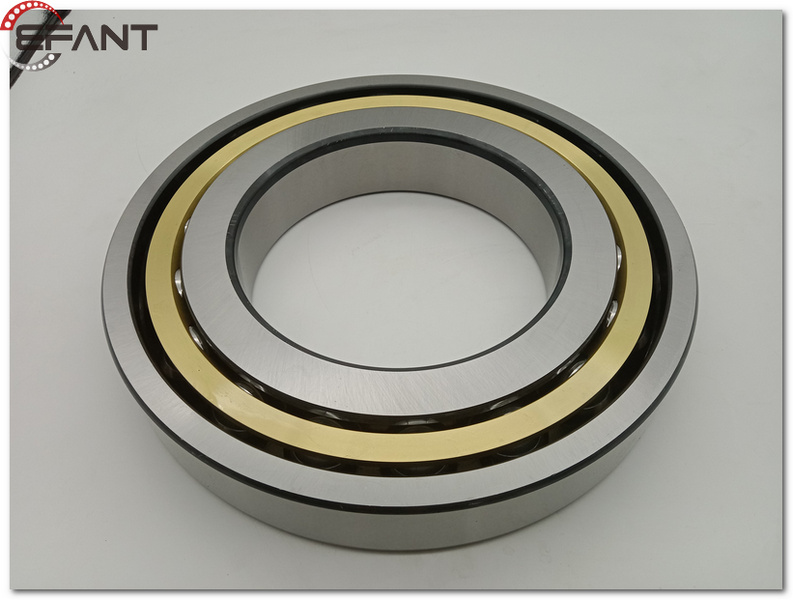

1.Deep Groove Ball Bearings: Deep groove ball bearings are widely used in semiconductor manufacturing due to their versatility and high-speed capabilities. They can accommodate both radial and axial loads and are suitable for applications requiring smooth and precise rotation, such as conveyor systems and spindle motors.

2.Angular Contact Ball Bearings: Angular contact ball bearings are designed to withstand high radial and axial loads and provide precise axial positioning. They are commonly used in semiconductor manufacturing equipment, such as wafer handling robots, where precise movement and load handling are critical.

3.Precision Bearings: Semiconductor manufacturing often requires high precision and accuracy in positioning and motion control. Precision bearings, including angular contact bearings, cylindrical roller bearings, and tapered roller bearings, are designed to provide exceptional accuracy and low runout. These bearings are used in various semiconductor manufacturing processes, including wafer handling, lithography systems, and inspection equipment.

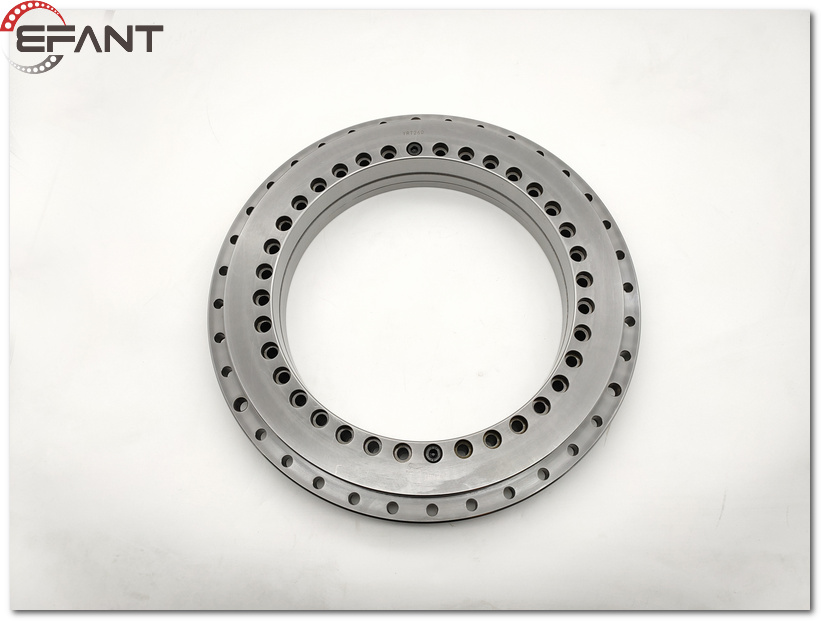

4.Crossed Roller Bearings: Crossed roller bearings have a unique design that allows them to handle both radial and axial loads simultaneously while maintaining high precision and rigidity. These bearings are often used in semiconductor manufacturing for applications that require high rotational accuracy, such as wafer handling stages, mask aligners, and lithography systems.

In semiconductor manufacturing, the choice of bearings depends on the specific application, load requirements, rotational speed, and environmental factors. It is essential to consider factors such as precision, rigidity, cleanliness, and durability when selecting bearings to ensure optimal performance and reliability in semiconductor manufacturing equipment.

May-18-2023

Trade Shows&Event

What’s the application ares of wind power bearings More InformationMay-12-2023

Trade Shows&Event

Can cylindrical roller bearings be used in X-ray machine More InformationMay-11-2023

Trade Shows&Event

What is the classification of industrial robot bearings More InformationSubmit Request