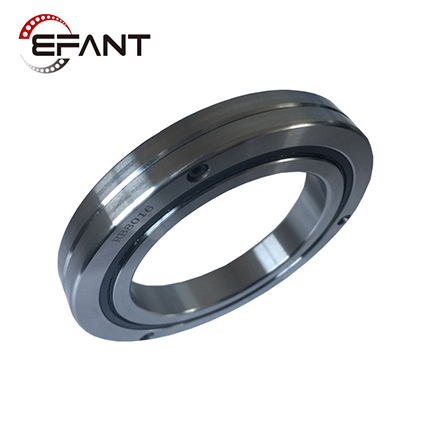

Cross roller bearings have their rollers arranged at right angles to each other at intervals between the inner and outer wheels. They can withstand loads from all directions simultaneously, such as axial, thrust, or momentum loads. Due to the current contact between the roller and the surface of the track, the possibility of elastic deformation of the shaft under load is very low. In cross roller bearings, because cylindrical rollers are arranged perpendicular to each other through spacer retainers on a 90 ° V-shaped groove rolling surface, one cross roller bearing can withstand loads in all directions, such as radial load, axial load, and torque load.

What are the characteristics of cross roller bearings?

Cross roller bearings, due to the divided inner or outer rings, are fixed together with the cross roller shaft ring after installing the rollers and spacer to prevent separation, so the installation of the cross roller shaft ring is simple. Due to the cross arrangement of the rollers, only one set of cross roller collars can withstand loads in all directions, which increases the rigidity by 3-4 times compared to traditional models.

Based on the above characteristics, what are the uses of cross roller bearings?

The size of the inner and outer rings of cross roller bearings is minimized. Cross roller bearings are particularly thin, which is close to the limit of small size and has high rigidity. Therefore, they are most suitable for joint or rotating parts of industrial robots, rotating workbenches of machining centers, rotating parts of robotic arms, precision rotating workbenches, medical machines, measuring instruments, IC manufacturing devices, and situations that require high rigidity, tightness, and high speed to still ensure accuracy.

Please feel free to contact us if you have any requirements.

Apr-09-2024

Trade Shows&Event

What are the advantages of cross roller bearings? More InformationApr-08-2024

Trade Shows&Event

What is cross roller bearing? More InformationApr-03-2024

Trade Shows&Event

What are the applications of bearings in the coal mining industry? More InformationSubmit Request